Product Center

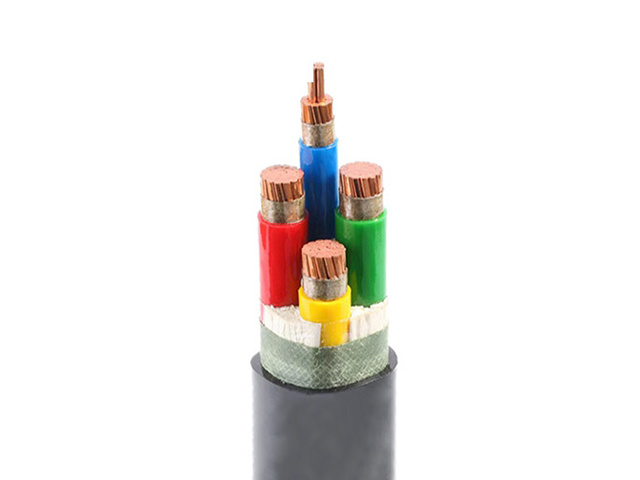

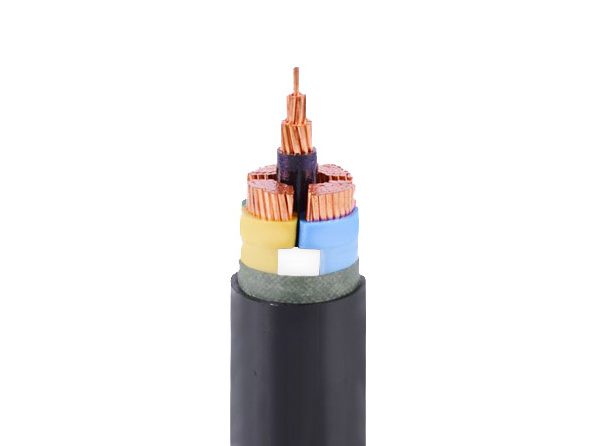

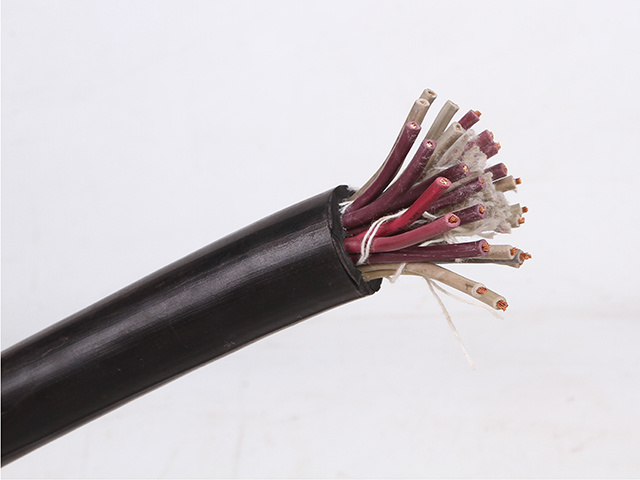

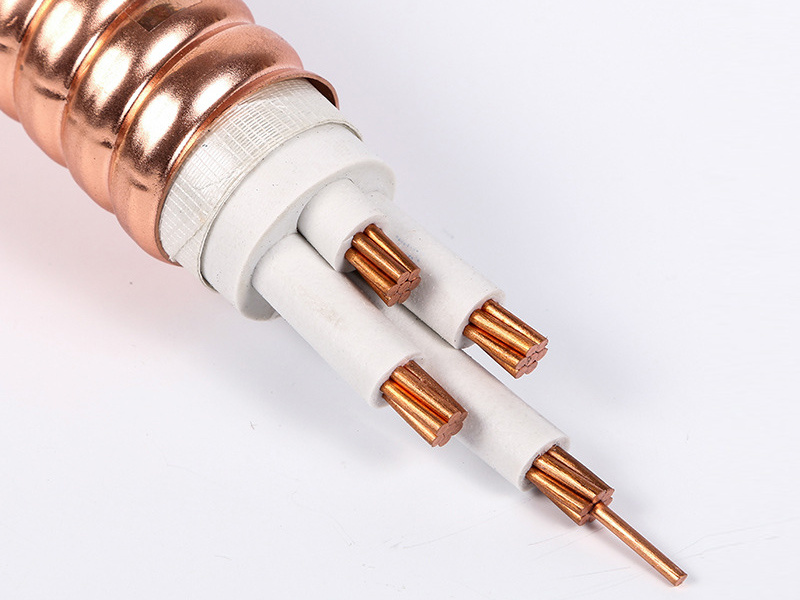

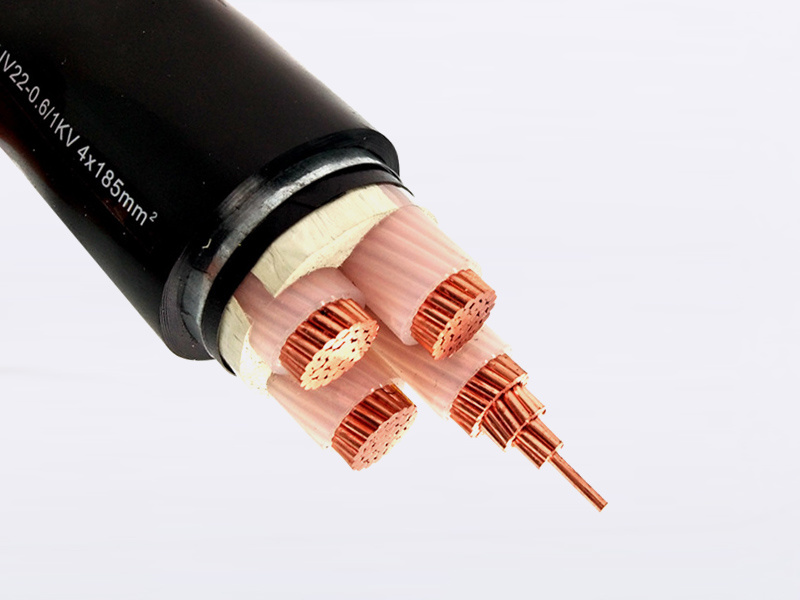

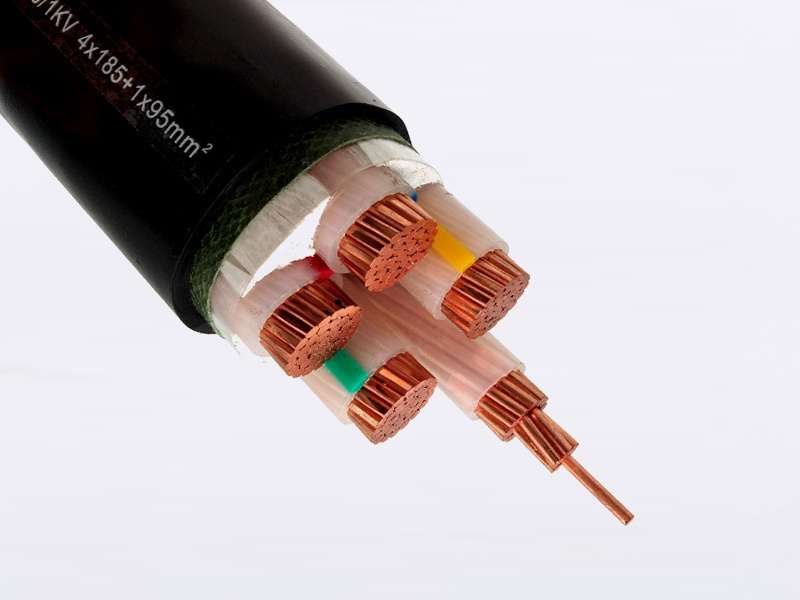

Our products include power cables, rubber-sheathed cables, mining cables, welding machine cables, low-smoke halogen-free cables, flame-retardant and fire-resistant cables, shielded cables, control cables, and a wide range of other wire and cable types. We are a company that integrates professional R&D, manufacturing, sales, and customer service into one comprehensive operation.

ABOUT US

Founded in 2000

Over 80 units of professional production equipment

Over 100 marketing technology service outlets

Guanghui Cable is a wire and cable enterprise integrating professional R&D, manufacturing, sales, and service. Currently, it operates a manufacturing base in Ningjin, Hebei, and has established over 100 marketing and technical service outlets across China. Relying on its strong reputation and consistently high product quality, the company has earned customer trust and successfully expanded into new markets. The company’s main product lines include power cables, rubber-sheathed cables, mining cables, welding machine cables, low-smoke halogen-free cables, flame-retardant and fire-resistant cables, shielded cables, control cables, and a wide range of other wire and cable products.

Why Us

Guanghui Cable Co., Ltd.

The company has established a comprehensive, efficient, and high-quality sales network that successfully serves customers across more than 20 provinces, municipalities, and autonomous regions nationwide.

Our strengths

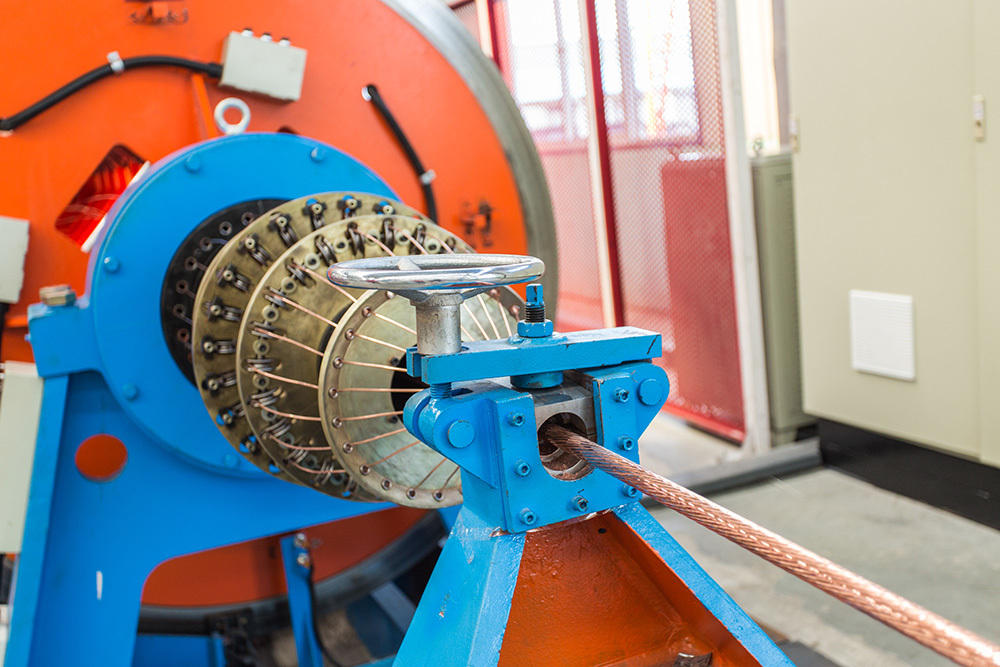

The company specializes in a wide range of wires and cables, including power cables, rubber-sheathed cables, mining cables, welding machine cables, low-smoke halogen-free cables, flame-retardant and fire-resistant cables, shielded cables, control cables, and more. We boast two advanced 6–35 kV three-layer co-extrusion dry crosslinking production lines, along with over 80 sets of specialized equipment for wire drawing, stranding, extrusion, shielding, cabling, and other critical processes.

Technology Advantages

We have two core production lines for 6-35 kV cables, backed by over 80 specialized pieces of equipment, and a collaborative industry-academia-research team dedicated to cutting-edge, eco-friendly, and energy-efficient power transmission technologies.

Market Reputation Advantage

20 years of dedicated expertise have earned the trust of 100 cities, with over 100 technical service centers spanning 20 provinces and municipalities across China—and we boast an extensive portfolio of international project experiences.

Service Advantages

From R&D to after-sales, we offer a one-stop solution, providing a comprehensive range of products—including power, mining, and flame-retardant options—suitable for diverse applications.

Blog

“Spreading light, illuminating the world”—this is the beautiful ideal that all Guanghui employees tirelessly pursue. The company sincerely looks forward to collaborating with friends from all walks of life to achieve mutual success and build a brighter future together!

2021-09-09

Primary applications of low-smoke, halogen-free cables

2021-09-09

Analyze how to improve the pass rate of fire-resistant cables in fire-resistance tests.

2021-09-09

Analyzing the Development Trends of Transformation and Upgrading in China's Cable Industry

Warmly Inviting You to Build Together

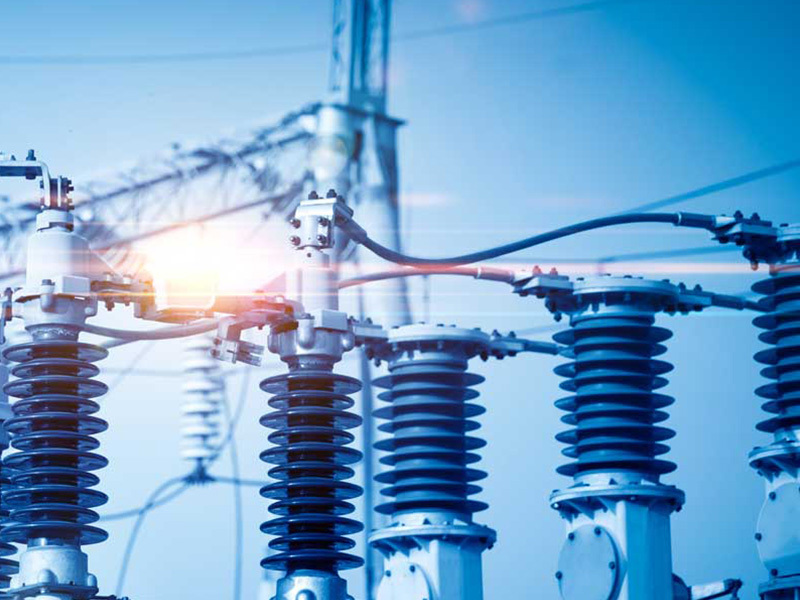

As a top 200 enterprise in China’s cable industry, Guanghui Cable leverages 20 years of technological expertise and a robust service network spanning over 100 locations to deliver comprehensive cable solutions—ranging from 6 kV to 35 kV—to customers worldwide. We invite you to join us in showcasing Hebei Province’s premium products, backed by our AAA-rated creditworthiness, and to explore deepened collaborations across key sectors such as energy, transportation, and construction.

Need help finding the right product?

Our expert team is ready to assist you at any time.

Contact Us →Do you have any questions?

For a quick response, please fill out the form, and our team will get back to you shortly.