CONTACT

TEL: +86-319-5986999

Phone:+86-15833709658

Email:602992806@qq.com

Address: No. 8 Simahuilong Street, Ningjin, Hebei

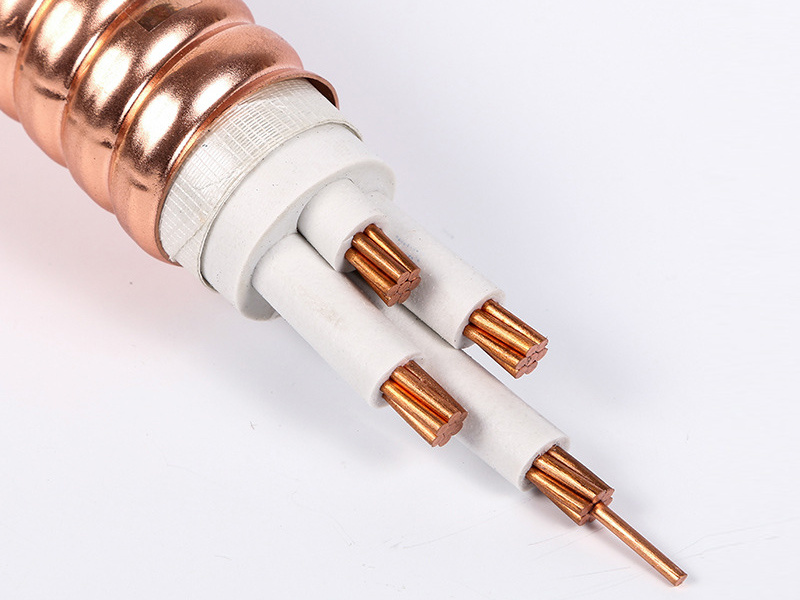

Flexible Fire-Resistant Cable

- Product Description

-

This standard is primarily based on GB/T 12706.1-2020, "Power Cables with Extruded Insulation and Their Accessories—Rated Voltages from 1 kV (Um = 1.2 kV) to 35 kV (Um = 40.5 kV)—Part 1: Cables Rated at 1 kV (Um = 1.2 kV) and 3 kV (Um = 3.6 kV)," as well as GB/T 19666-2019, "General Specifications for Flame-Retardant and Fire-Resistant Wires and Cables." This product is designed for use in critical electrical engineering applications, including hazardous areas such as airports, oil depots, liquefied gas stations, chemical plants, coal mines, nuclear power plants, steel mills, and shipyards; advanced and essential public facilities like satellite ground stations, railway wiring systems, alarm systems, and fire protection networks; and environments where safeguarding human life and property is paramount, such as historic buildings, hotels, high-rise structures, museums, libraries, banks, hospitals, insurance institutions, shopping malls, and research facilities.

Product Models and Naming

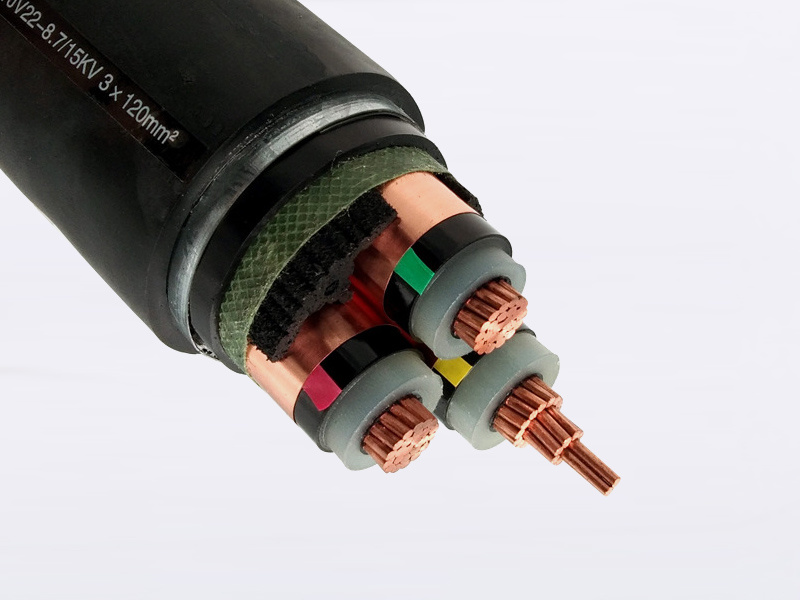

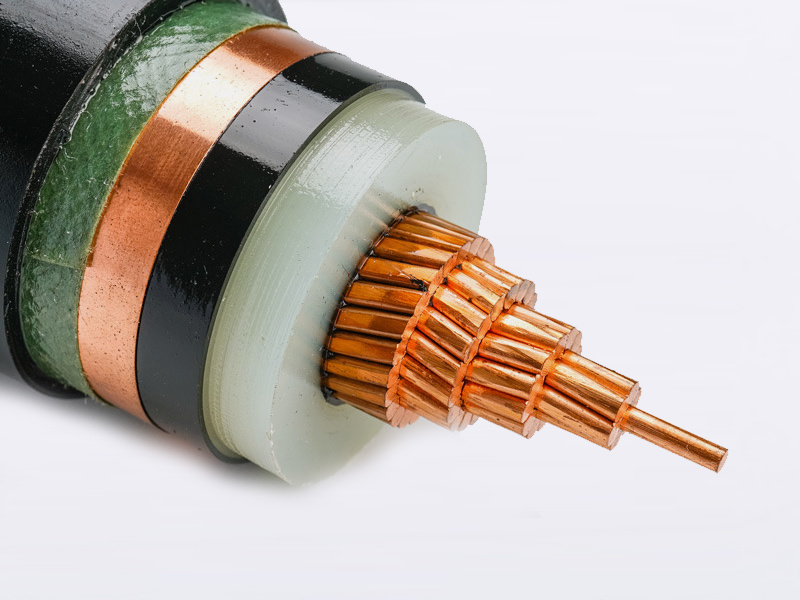

Model Name YTTW Copper-core, embossed copper-sheathed, inorganic mineral-insulated flexible fire-resistant cable YTTWV Copper-core, embossed copper-sheathed, inorganic mineral-insulated, PVC-sheathed flexible fire-resistant cable YTTWY Copper-core, embossed copper-sheathed, inorganic mineral-insulated, polyolefin-based, corrosion-resistant, flexible fireproof cable with an external protective jacket. Product Specifications

Model Rated Voltage Number of cores Nominal Cross-Sectional Area / mm² YTTW

YTTWV

YTTWY450/750V

0.6/1 kV1 1.0 to 630 2 1.0 to 300 3 1.0 to 240 4 1.0–185 3 + 1 3 × 16 + 1 × 10 3 × 25 + 1 × 16 3 × 35 + 1 × 16 3 × 50 + 1 × 25 3 × 70 + 1 × 35 3 × 95 + 1 × 50 3 × 120 + 1 × 70 3 × 150 + 1 × 70 3 × 185 + 1 × 95 3 × 240 + 1 × 120 3 + 2 3 × 25 + 2 × 16 3 × 35 + 2 × 16 3 × 50 + 2 × 25 3 × 70 + 2 × 35 4+1 4 × 16 + 1 × 10 4 × 25 + 1 × 16 4 × 35 + 1 × 16 4 × 50 + 1 × 25 4 × 70 + 1 × 35 5-7 1.0–4.0 12-37 1.0–2.5 Nominal thickness of the copper sheath

Nominal cross-section / mm² Nominal thickness of copper sheath / mm 1-core 2-core 3-core 4-core 5-core 7-core 12-core 19-core 24-core 30-core 37-core 1.0 0.4 0.4 0.4 0.4 0.45 0.45 0.4 0.4 0.4 0.4 0.4 1.5 0.4 0.4 0.4 0.4 0.45 0.45 0.4 0.4 0.4 0.4 0.4 2.5 0.4 0.4 0.4 0.4 0.45 0.45 0.4 0.4 0.4 0.4 0.4 4 0.4 0.4 0.4 0.4 0.45 0.45 / / / / / 6 0.4 0.4 0.4 0.4 0.45 0.45 / / / / / 10 0.4 0.45 0.45 0.45 0.5 0.5 / / / / / 16 0.4 0.45 0.45 0.5 0.5 / / / / / / 25 0.4 0.5 0.5 0.5 0.5 / / / / / / 35 0.45 0.5 0.5 0.5 0.5 / / / / / / 50 0.5 0.5 0.5 0.6 0.6 / / / / / / 70 0.5 0.5 0.6 0.6 0.6 / / / / / / 95 0.5 0.5 0.6 0.6 0.6 / / / / / / 120 0.5 0.5 0.6 0.6 0.6 / / / / / / 150 0.5 0.6 0.6 0.7 0.7 / / / / / / 185 0.5 0.6 0.6 0.7 0.7 / / / / / / 240 0.6 0.6 0.6 0.7 0.7 / / / / / / 300 0.6 / / / / / / / / / / 400 0.6 / / / / / / / / / / 500 0.6 / / / / / / / / / / 630 0.6 / / / / / / / / / / Note: For core counts not listed, the nominal thickness of the copper jacket should be set to the nearest value specified for the corresponding core count.

Contact us

TAG: