CONTACT

TEL: +86-319-5986999

Phone:+86-15833709658

Email:602992806@qq.com

Address: No. 8 Simahuilong Street, Ningjin, Hebei

Copper-core polyvinyl chloride insulation

- Product Description

-

Common insulated wires—such as household electrical cables—are the most widely used type of wiring. Taking a 100-square-meter new home as an example, you’d need 200 meters of 4-square-millimeter copper-core BV wire, 400 meters of 2.5-square-millimeter wire, and 300 meters of 1.5-square-millimeter wire. Additionally, 100 meters of 1.5-square-millimeter copper-core BV two-color wire would be required. Note that this calculation assumes no installation of a false ceiling; if you plan to add one, you’ll need slightly more of the 1.5-square-millimeter wire.

Common insulated wires—household electrical cables—are the most widely used type of wiring. Taking a 100-square-meter new home as an example, you’d need 200 meters of 4-square-millimeter copper-core BV wire, 400 meters of 2.5-square-millimeter wire, and 300 meters of 1.5-square-millimeter wire. Additionally, 100 meters of 1.5-square-millimeter copper-core BV two-color wire would be required. Note that this calculation assumes no吊顶 (false ceiling) installation; if you plan to add a吊顶, you’ll need slightly more of the 1.5-square-millimeter wire.

Advantages of electrical wires:

According to national standards GBT5023-2008, JBT8734-2012, and the mandatory certification requirements for electrical and electronic products (CCC), the conductors are made from high-quality oxygen-free copper, ensuring excellent conductivity and minimal heat generation—perfect for extended, heavy-duty applications. The insulation is crafted from premium-grade plastic, offering robust insulation properties that are both wear-resistant and flame-retardant, guaranteeing a long service life. BV cables feature a single-core copper wire, making them stiffer and slightly more challenging to install, but they boast superior strength. In contrast, BVR cables consist of multiple stranded copper wires, providing greater flexibility for easier installation—but at the cost of slightly reduced tensile strength.

BV single-core copper wire is typically used in fixed installations; BVR wire, on the other hand, features a copper core with flexible PVC insulation, making it ideal for applications requiring flexibility—commonly in situations where slight movement occurs. Additionally, multi-strand BVR cables can carry higher current loads compared to single-strand wires, though they come at a slightly higher price. Inside electrical cabinets, BVR wire is often preferred because it doesn’t need to withstand extreme mechanical stress, yet still offers convenient wiring options.

Product specifications:

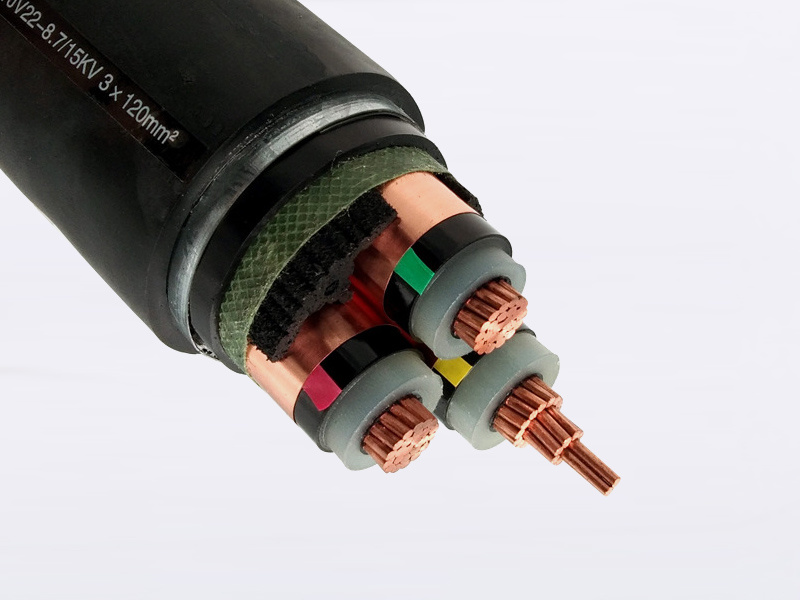

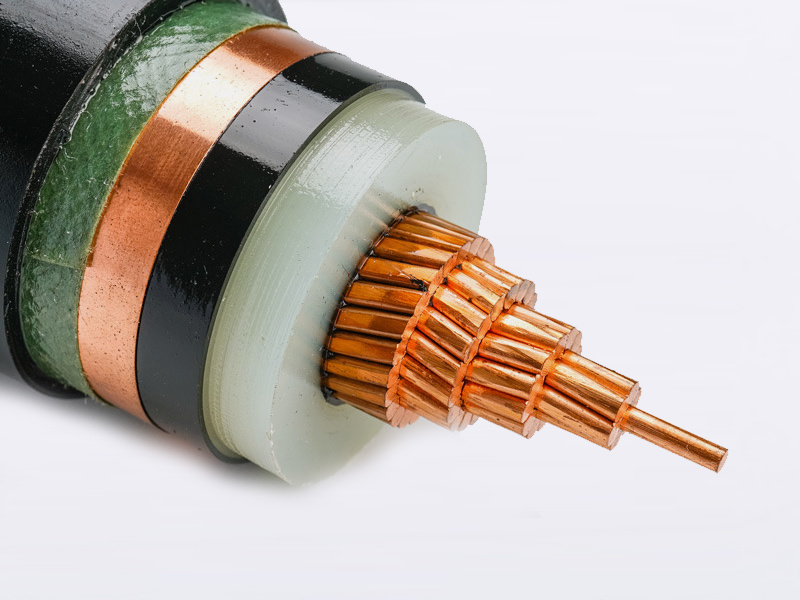

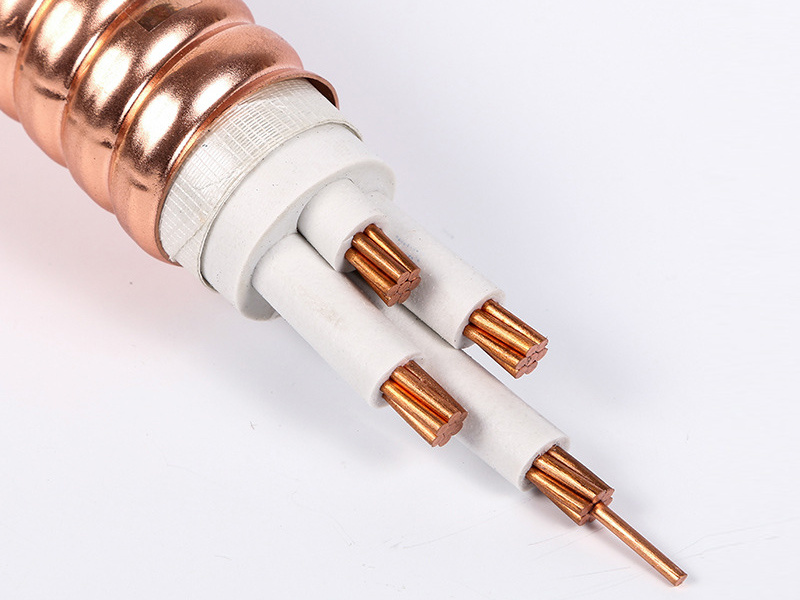

Product Structure: Conductor + insulation. The primary material for the conductor is typically oxygen-free copper, composed of multiple strands of copper wire, while the insulation is made of PVC.

Implementation standard: JB/T 8734-2012 GB/T 5023-2008.

Quality standards: 3C Certification

Rated voltage: The wire was submerged in water for 1 hour and then subjected to an AC voltage test of 2500V (450/750V) at 50Hz and 2000V (300/500V), both lasting 5 minutes, without experiencing breakdown.

Operating temperature: The maximum operating temperature should not exceed 70°C under normal conditions, while the BVR-105 type can withstand a maximum operating temperature of up to 105°C. Additionally, the installation temperature of the wire must be no lower than 0°C.

Allowable bending radius: For wires with an outer diameter (D) less than 25 mm, the bend radius should be no less than 4D; for wires with an outer diameter (D) of 25 mm or greater, the bend radius should be no less than 6D.

Colors: Red, yellow, blue, green, black, brown, yellow-green, white, and more—custom options available upon request.

Usage: Suitable for circuits with rated AC voltages of 450/750V and below, used in power systems, household appliances, instruments, meters, telecommunications equipment, and more—particularly ideal for integration into various mechanical devices due to its excellent flexibility.

Contact us

TAG: