CONTACT

TEL: +86-319-5986999

Phone:+86-15833709658

Email:602992806@qq.com

Address: No. 8 Simahuilong Street, Ningjin, Hebei

Polyvinyl chloride cable

- Product Description

-

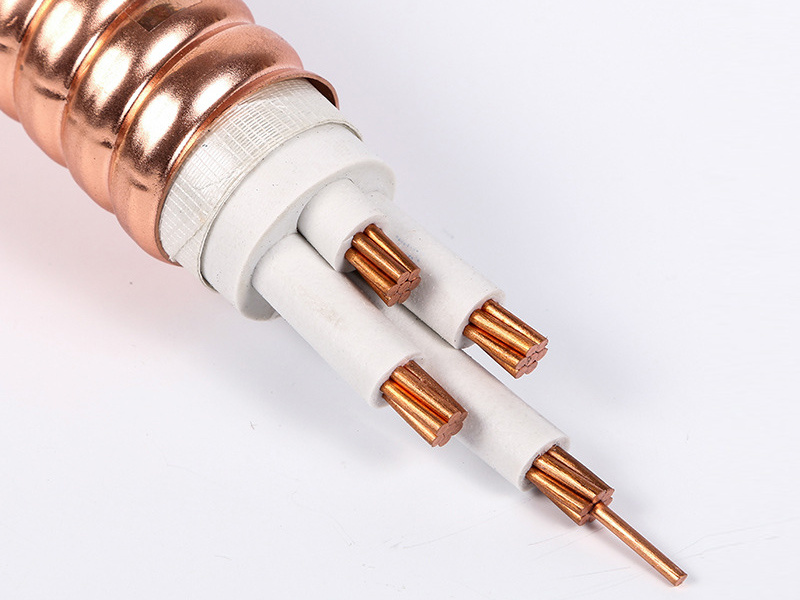

Made from imported, eco-friendly cross-linked polyolefin, this premium wire model boasts exceptional flexibility, is highly resistant to bursting, offers excellent flame-retardant properties—meaning it won’t catch fire—and produces minimal smoke, nearly eliminating it altogether. Additionally, it emits no toxic gases, making it the ideal choice for high-end home renovations.

Product Description:

WDZ-BYJ is an upgraded, next-generation, flame-retardant cross-linked low-smoke halogen-free polyolefin product that adheres to the IEC 227 standard for environmentally friendly materials. It boasts exceptional flame retardancy, low smoke emission, and minimal toxicity, effectively addressing the drawbacks of conventional halogenated polymers—namely, the release of dense, toxic fumes during combustion, which can lead to suffocation and damage sensitive equipment. As such, WDZ-BYJ epitomizes the current trend in the development of wires and cables.

The halogen-free, low-smoke, low-halogen, and smoke-free properties of WDZ-BYJ wires ensure that, in the event of a fire, they burn more slowly, produce less toxic smoke, maintain high visibility, and emit minimal harmful gases—making it easier for people to evacuate safely from the disaster site. Additionally, when these low-smoke, halogen-free cables ignite, the resulting gases exhibit extremely low corrosivity, effectively preventing damage to sensitive instruments and equipment. Thanks to their exceptional resistance to aging, UV radiation, and other forms of environmental stress, these cables significantly enhance overall performance, ultimately extending the service life of various types of cables.

Technical specifications:

Test items for finished cables, such as conductor resistance, insulation resistance, withstand voltage tests, and partial discharge tests, follow the standards applicable to conventional cables.

For low-smoke, low-halogen cables during combustion: halogen acid gas emission ≤ 0.00 mg/g, with a minimum light transmittance of 60%.

Low-smoke, halogen-free cables have a pH value ≥4.3, an electrical conductivity ≤10 μS/mm, and a minimum light transmittance of 60% when burned.

Contact us

TAG: